Fan Energy Index (FEI)

About this article

Fan Energy Index (FEI) is a metric defined by AMCA that measures the energy efficiency of a fan at a specific operating point by comparing it to a reference fan. FEI is used to evaluate fan performance, support energy regulations and guide efficient fan selection in HVAC and industrial applications.

The purpose of this article is to share our knowledge of the Fan Energy Index (FEI), our experiences in implementing it within fan selection software, and our thoughts on why FEI is so important for improving fan efficiency across the industry. Whether you are exploring FEI for the first time or already have some knowledge of AMCA-certified fan performance standards, we hope that by sharing our experience we can help move the industry toward a more efficient world of air movement.

The need for better fan efficiency

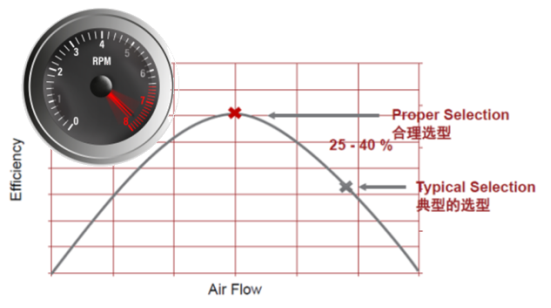

With fans, unlike many other electrical appliances, the operating efficiency can vary widely depending on how they are selected and used in their real-world operating environments. A fan manufacturer will provide performance information for their products taken from the results of their testing. However, it is unlikely that the fan will operate at the same duty point, airflow or pressure conditions as it was tested. As a result in a lot of cases, many fans run significantly below their peak energy-efficient operating range. If you look at the efficiency curve of a fan with respect to airflow, it has its peak towards the middle of the possible airflow envelope. It is at, or around, this optimal point that a proper FEI-based fan selection should be made using accurate fan selection tools. In commercial reality fans are often selected at a much reduced efficiency because they can still meet the operating point but they are smaller than required with a smaller upfront cost.

If you consider all the fans in the world running in-efficiently with an unnecessarily large power requirement there is a huge waste of energy. This energy has to be generated and has commercial and environmental factors that should be considered highlighting the need for better industrial fan efficiency, AMCA-standard fan performance and more accurate selection through modern fan energy index software.

Previous fan efficiency metrics before FEI

Prior to the emergence of the Fan Energy Index (FEI) with the AMCA 208 in 2018 and AMCA 214 in 2021, the industry relied on two older fan efficiency metrics: the Fan Efficiency Grade (FEG) defined in AMCA 205-11, and the Fan Motor Efficiency Grade (FMEG) defined in IEC 61800-9-2. These metrics were widely used in fan performance analysis before FEI became the industry’s preferred AMCA-certified efficiency standard.

A FEG rating applies only to the fan itself and is based on the fan’s peak total efficiency at a specific test point under controlled laboratory conditions. It considers the size of the fan and calculates efficiency using the relationship between air power out and the shaft or absorbed power in. However, because FEG is a single-point metric, it does not reflect the broad range of real-world operating conditions encountered during actual fan selection and installation.

FMEG rating is similar to FEG but in addition to the fan wheel it also takes into account the motor, transmission and drive components. It is what is called a ‘wire to air’ metric which means its measure of efficiency calculated from the air power out in relation to the electric power in. It is a single point metric again taking into account the peak (best) efficiency of the system.

So FMEG is a more complete metric than FEG and both were a step in the right direction in trying to improve efficiency by using standards. However the share the same flaw being single point metrics. It is highly unlikely that the fan will be operating at the same speed and conditions as where the single point peak value was measured. Due to the nature of a big efficiency differences across the operating envelope of the fan, it’s safe to say the measured value probably isn’t relevant to the actual fan being installed.

A more rigorous approach was needed and from 2011 the Department of Energy (DOE) in the US, together with AMCA started to look at something that could be a true measure of efficiency in the field and in 2018 the AMCA 208 the Fan Energy Index specification was released.

The principles of the Fan Energy Index (FEI) and how to calculate it

As with FMEG, FEI is a ‘wire to air’ metric but it has a fundamental difference not being a single point metric using peak values obtained during testing. It can be calculated for any operating point within the operating range of a fan assembly. This is very important as it makes the metric far more applicable to how the fan is being used and the operating point demands put on it. In short it should prevent an efficient fan being used in an inefficient way.

So we need to look at how FEI is calculated and achieves its aims. Unlike any other previous metric it makes use of a notional reference fan with a maximum allowable calculated power requirement and compares it with the power requirement of the actual fan being analysed.

The FEI calculation can be seen as this:

FEI = Reference Fan Electrical Input Power (FEP) / Actual Fan Electrical Input Power (FEP)

Where both fans provide the same operating point

We are therefore looking at the ratio of the electrical power required by the notional fan and the actual fan. If the actual fan power consumption is greater than the reference fan the FEI value will be less than 1. If it is less than the reference fan the FEI value will be greater than 1. This makes the FEI metric very easy to understand with any value of above 1 being acceptable. Notably, there has been discussion on using a slightly higher number than 1 for regulation at some future point, but 1 is the general value in use at the moment.

Whilst the main FEI calculation appears simple it does get quite involved as we need to calculate the input electrical power of both fans.

Calculation of the reference fan electrical input power depends on a factors such as the fan, installation and transmission types. Calculation of the actual fan electrical input power is relatively straightforward and where motor efficiency values are not available at the operating point the AMCA 207 FEP specification can be used to estimate it for TEFC and ODP motors.

Rather than go further into these calculations here, fortunately we have the AMCA 207, 208 and 214 specifications which are very well-written and make the process as simple as possible. We recommend you look at them if implementing FEI.

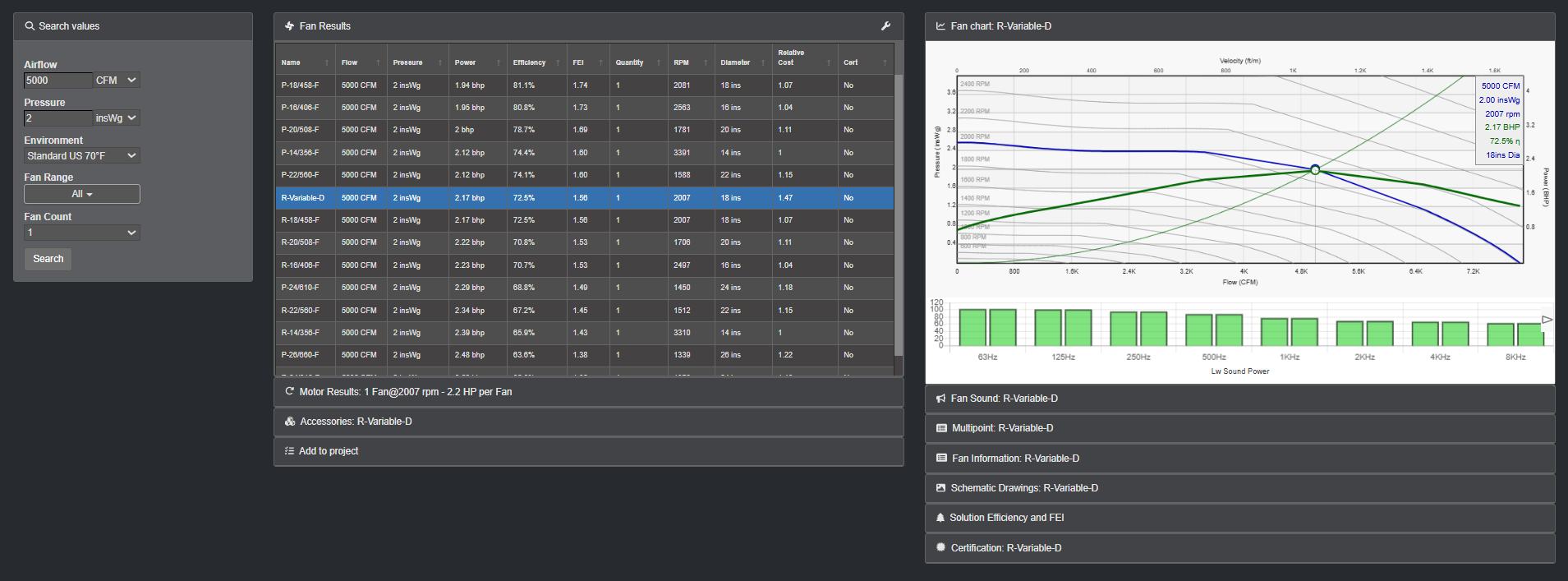

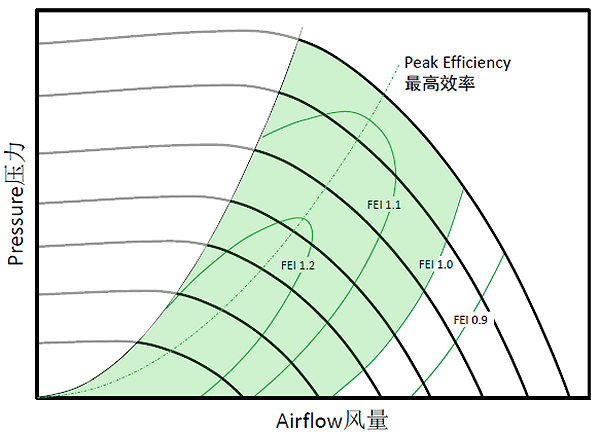

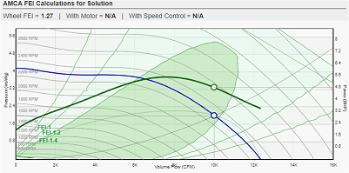

Using FEI bubbles to visualise

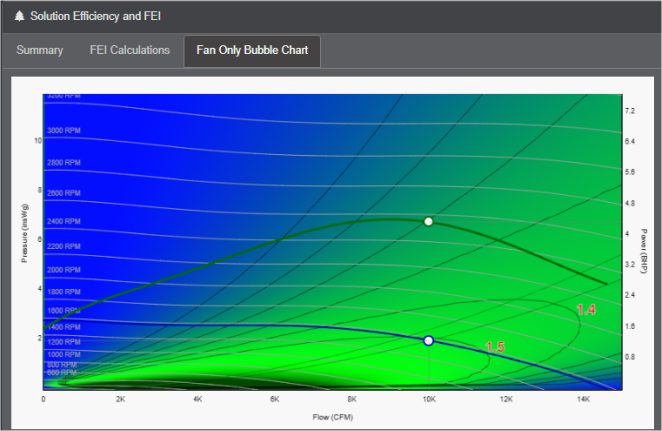

On a fan performance chart, our fan software draws FEI bubbles which are visual areas on a performance chart that represent zones of constant FEI values

When we are selecting a fan for an airflow requirement we can calculate its corresponding FEI which can help gauge its relative efficiency and regulatory compliance in some cases.

We can also use FEI for analysis of a fan with lines of constant FEI value on a fan chart. These could be viewed in the context of looking at lines of constant efficiency which normally provide a shape similar to a circle. If we draw lines of constant FEI values of 1, 1.1, 1.2 etc we should see the corresponding lines enclose shapes in the form of bubbles which are called ‘FEI bubbles’

These bubbles give a great visualization of good areas of fan selection on a fan chart at a glance.

The mathematics behind drawing the bubbles can be quite complex and can consume significant computing power.

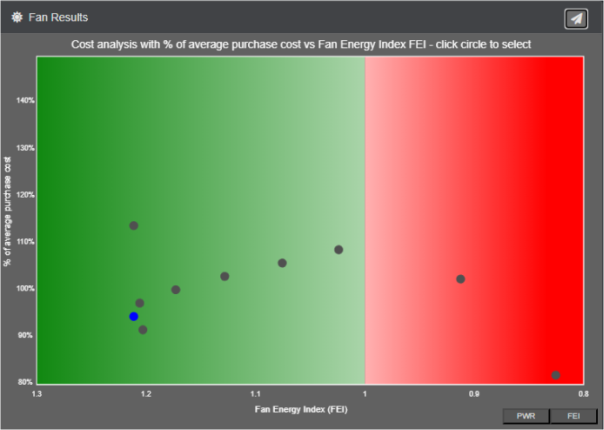

The importance of FEI

When implementing FEI into fan selection software one natural trend is easily seen – bigger fans running slowly are more efficient than smaller fans running quickly for the same operating point. Having this clear single numeric makes the whole process of complete efficiency assessment very clear and understandable across the numerous applications where fans are used.

In the competitive fan supply market, the cheaper, less efficient fans will always win out, even if in the long term the operator faces much higher running costs which dwarf the (minor) initial upfront savings. So FEI is a measure that can be easily used in regulation if that is necessary.

A good way of looking at FEI is not that it forces the selection of the most efficient fan rather than it can help prevent selecting fan that are not efficient enough at a particular operating point.